Features of ST-927

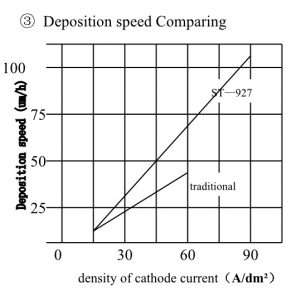

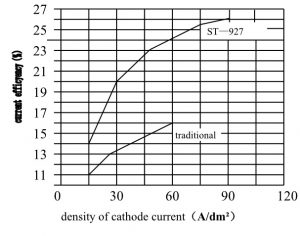

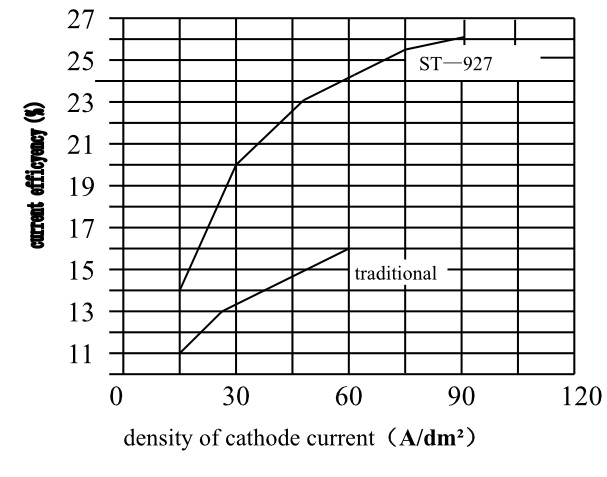

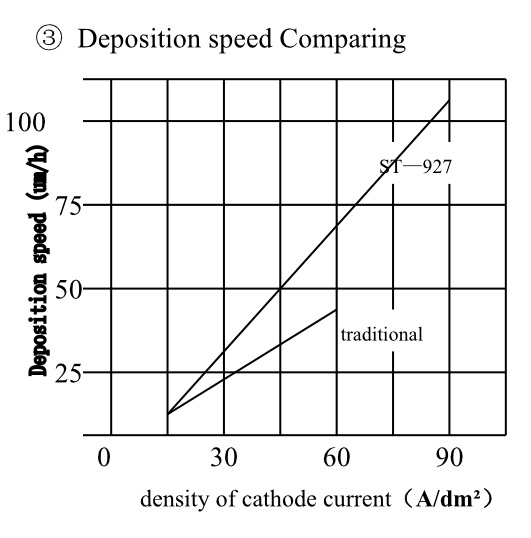

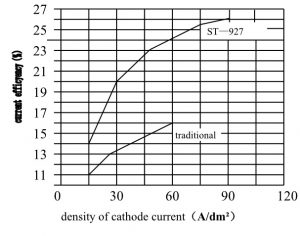

- More efficient cathode current (as high as 22%-28%), high speed of sedimentary, which is twice as fast as traditional Under the conditions as following, density of cathode current 60A/dm2, temperature 55-65℃, current efficiency is high up to 60um/h.

- High hardness of chrome layer, which is 900-1260 HV against GB9790-88 Standard. And durability is higher by 20%-30%.

- More micro cracks in chrome layer, which is 400-1500 pieces/cm2, and it is more anti-corrosion compared with traditional

- Chrome layer is combined with base more intensely, and the pre-process operation is more simple.

- Chrome solution dispersesbetter, and the thickness of layer is more even, the surface is more smooth, hardly leaving any knurls.

- There is no fluoride in chrome solution, so it prevent the work pieces from corrosioncaused by lower current during electro plating.

- Anode solution conducts well, there is less corrosionto anode.

- Lower labor cost and fuel consumption by 2 times, evidently shorten metal processing time.

Elements and Operation Standards of Chrome Plating ST-927 Technology

- CrO3 180-240g/L

- Plating Bath Solution temperature 55-65℃

- H2SO4 1.8-3.4g/L

- Cathode current density: 30-80A/dm2

- Cr3+ 1.0-4.0g/L

- Anode material ST-927EK 16-20ml/L (lead-tin alloy catalyst which includes 7%-15% tin)

Plating Bath Solution Formula of ST-927 Technology

New solution is formulated as following: CrO3 200g/L, ST-927EK 20ml/L (or intermediate DX-30 4g/L),

Then add some H2SO4 to make CrO3:H2SO4 rate is between 1.5-1.0:100.

STEPS:

- Add 2/3 volume of deionized water in clean plating bath, which can not contain any chloride or sulfate ion, and heat it to 45-50℃.

- Stir the liquid continuouslyand add the CrO3 at the same time.

- Stir continuouslyand add ST-927EK and H2SO4

- Stir the solution evenly, add deionized water to full volume. Test the solution density, adjust the element if necessary.

- Heat the solution to 55-65℃, add proper amount of anti-fog chemicals approved by our company.

- Test the plating effect after electrolysis lasts for 0.5-1 hours.

Plating Bath Solution Transfer

It has to be tested and studied by our company before transferring the plating bath solution.

For the traditional tech, we can adjust the contents of CrO3 and H2SO4 to the proper rate against the ST-927 standard, and then add ST-927EK.

For other technology, generally speaking, directly add ST-927EK and adjust the amount of elements against actual conditons.

Note: The performance of plating solution after transfer is somehow influenced by original one, clients should keep us informed with any possible sitiations.

Supplements and Maintain of Plating Bath Solution

The consumption of CrO3 and catalyst has to be calculate by 1000Ah unit. Add 7ml ST-927EK and CrO3 115g per 1000Amh during plating, or every time add 100kgs of CrO3, simultaneously add 5kgs of ST-927EK, to keep the rate steady between CrO3 and catalyst. Reduce the consumption caused by convulsion as less as possible, recycle the solution with clean water, lower the waste and prevent the solution from disproportionation. Supplement is conducted against the above standard, during production, adjustment is made according to actual conditons.

Other Concerns and Notices

- There should be enough volume for rectifier device to meet the high density current flow, the lowest density current is no less than 20A/dm2, as low density current would reduce the current flow efficiency.

Voltage 12-15V, derect-current output, ripple factor≤3%.

- Heating and cooling devices should be well equipped to guarantee the temperature required by ST-927 tech, and make the solution be heated evenly. The stir machine is required to make the chemicals and temperature disperse evenly.

- Pre-process: Utilize the clean chemicals approved by our company. It’s suggested to use ST-104A ( one kind of manual cleaner) and ST-104C (electrolysis Degreasing chemicals), both of them are especially designed for ST-927 tech. Work piece must be completely cleaned before put into the both to assure of the quality of electro plating.

- Anti-fog chemicals: Utilize qualified anti-fog chemicals approved by our company, such as F-53.

- Anode material (lead-tin alloy catalyst which includes 7%-15% tin), it is recommended use the material contains 15% of Tin.

- Impurities: the amount of metal ion should be under level of 8g/L, chloride is no more than 100ppm.

- It is recommended to utilize high density current together with proper temperature. As temperature goes higher and current density goes down, it would slow the current efficiency.

- Impurities: the amount of metal ion should be under level of 8g/L, chloride is no more than 100ppm.

- It is recommended to utilize high density current together with proper temperature. As temperature goes higher and current density goes down, it would slow the current efficiency.

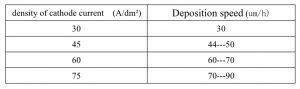

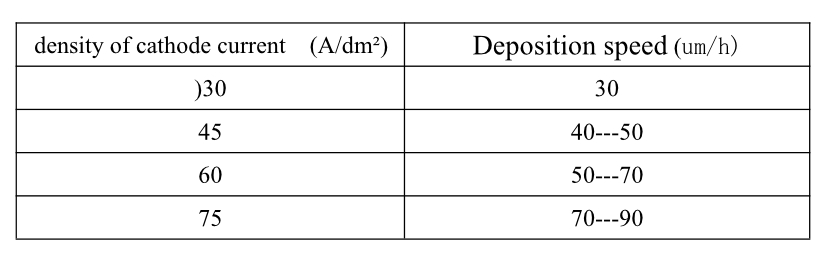

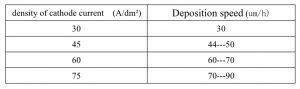

Reference value

① Deposition speed

② current efficiency Comparing

③Deposition speed comparing